Working Wonders in Wire for more than a century

Who knew?

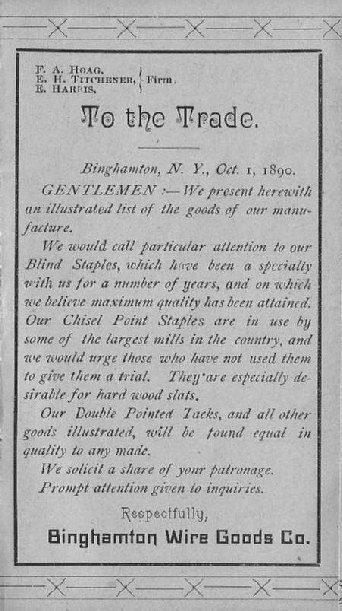

That Binghamton was one of the early centers of staple manufacturing in the 1880s?

That Titchener’s pioneered glued-together strips of staples, an innovation that made staplers possible in the early 1900s?

That Titchener’s made staples of all shapes and sizes from 1880 until 2005?

That Titchener wire products are used

in cash registers to hold bills?

inside computers to keep components cool?

to hang chickens by their feet in automated plucking lines?

in hospitals to sterilize equipment?

in clean room manufacturing of computer chips?

as hooks on military tents in Afghanistan and Iraq?

E. H. Titchener Company, one of the longest surviving metal forming manufacturers in Greater Binghamton and home to generations of ingenious tool and die makers, closed in Spring 2005. A ton of welding jigs and prototypes and more than 100 boxes of company records, including catalogs from the 1880s, mid-20th c. advertising material, photographs, customer files and drawings from the 1950s – 2005, were donated to CT&I.

Through the generosity of the Victor and Ester Rozen Foundation, CT&I acquired four early 20th c. staple making machines and a small four-slide machine, capable of bending narrow-gauge wire into complex shapes. The E. H. Titchener collection also includes hand-tools, work tables, spools of wire, and other factory accessories that preserve the local legacy of tool making and wire bending. Exhibits and hands-on activities based on this equipment and recordings of veteran Titchener employees have the potential to generate excitement in solving real-world problems with geometry and insight among young and old museum visitors.

![Laboratory[1].jpg](https://images.squarespace-cdn.com/content/v1/567433669cadb6ac8da3ff92/1464132446863-WYU24XQU9GD253610LJH/Laboratory%5B1%5D.jpg)